Mining

KASIYA MINING TRIALS COMPLETED SUCCESSFULLY

December 19, 2024 / Marcel Chimwala

By Marcel Chimwala

ASX-listed resources firm Sovereign Metals has announced that it has successfully completed the mining trials stage of its Pilot Mining and Land Rehabilitation Program (Pilot Phase) at the Kasiya Rutile-Graphite Project in Lilongwe, Malawi.

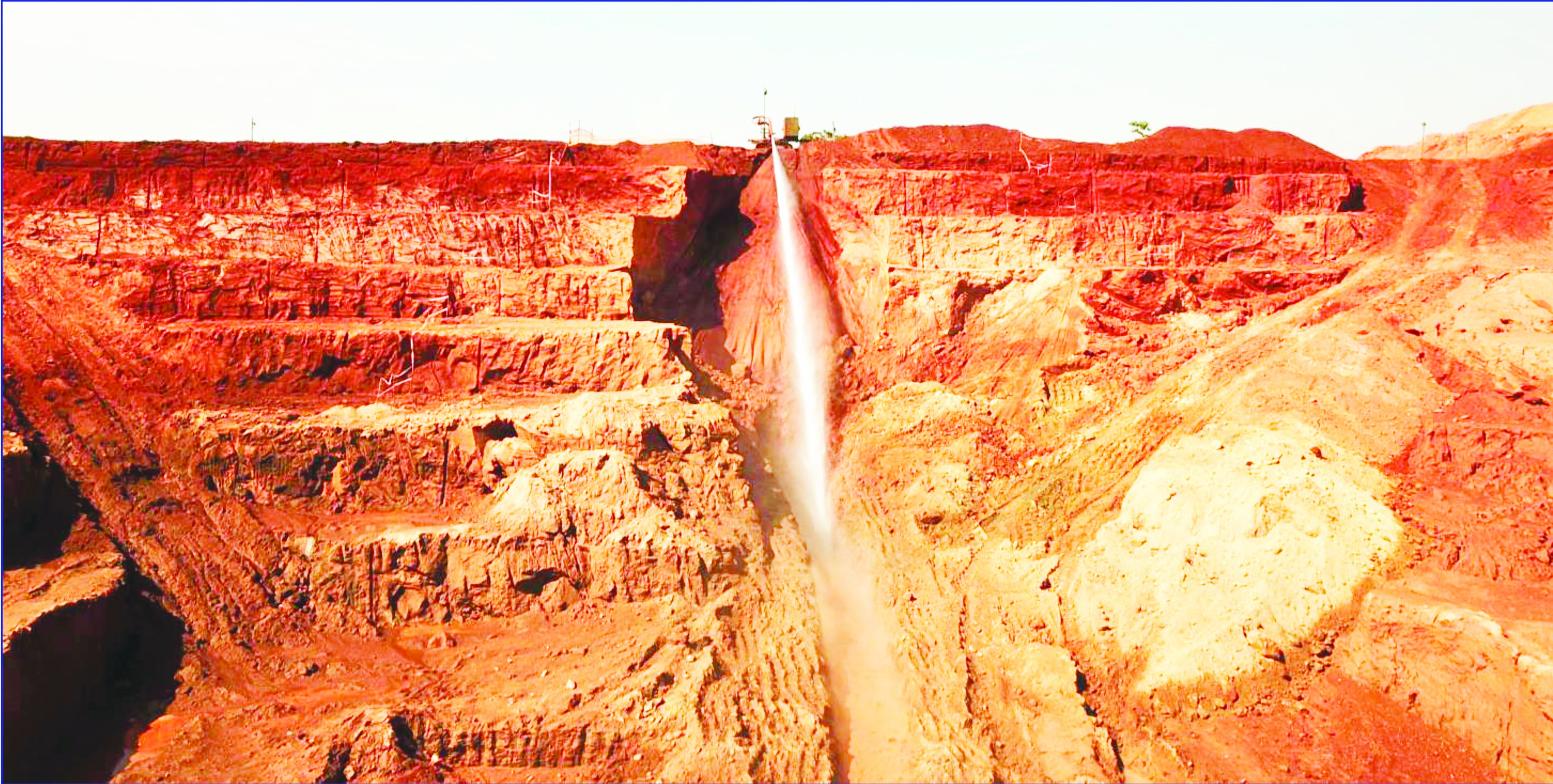

Hydraulic mining trials at Kasiya were successfully concluded as part of the Kasiya Optimisation Study. Prior to the hydraulic mining trials, a dry mining trial successfully excavated a test pit to a depth of 20 metres. The mining trials confirm that the soft, friable Kasiya ore can be efficiently mined.

MD and CEO Frank Eagar commented in a Press Statement: “I am pleased with the results of the mining trials at the test pit and now look forward to the rehabilitation demonstration stage, with the backfilling of the pit already underway.”

“Our findings from this Pilot Phase are continuously improving our understanding of Kasiya and how to optimise operations at this genuine Tier 1 project.”

Eagar reports that following the conclusion of mining trials, land rehabilitation demonstrations are now underway commencing with the backfilling of the test pit.

The test pit, which was excavated using conventional dry mining techniques and a simple mobile excavator fleet, covered an area of 120 metres by 110 metres and was mined to a depth of 20 metres through the weathered ore at Kasiya.

Eagar reports that mined material is being placed back into the pit and all areas will be graded. The backfilling stage is expected to conclude in December 2024.

He says as part of the Pilot Phase, the Company has constructed small rehabilitation demonstration pits that will be used to demonstrate various rehabilitation processes.

“Sovereign’s objective is to restore land after mining to conditions that achieve the same or better agricultural yields than prior to mining operations,” he states.

The Pilot Phase will demonstrate to local communities the successful rehabilitation of land for agricultural use post-mining. Eagar explains that results will also allow Sovereign to determine optimal approaches, providing critical information for Kasiya’s Environmental and Social Impact Assessment.

Eagar says: “Sovereign remains focused on becoming a leading global supplier to the titanium and graphite industries. Kasiya is the world’s largest natural rutile deposit – the purest, highest-grade naturally occurring titanium feedstock – and the world’s second-largest flake graphite deposit – a battery mineral essential for the energy transition.”

Fraser Alexander, a global industry leader in hydraulic mining, conducted the trial which commenced in August.

The dry mining trial confirmed Kasiya can be efficiently mined to depth using standard mobile excavators and trucks.

The Pilot Phase program continues to progress with oversight from Sovereign-Rio Tinto Technical Committee.

Rutile

Rutile is the purest, highest-grade naturally occurring form of titanium. Kasiya is the largest rutile deposit in the world with a Mineral Resource Estimate of 1.8Bt at 1.0% rutile resulting in 17.9Mt tonnes of contained natural rutile.

Titanium is found in nature in two main feedstock forms. Natural rutile (95%+ TiOâ‚‚), which requires little-to-no beneficiation from its natural form and Ilmenite (30-60% TiOâ‚‚), which requires energy and is carbon-intensive upgrading before it can be used in titanium metal or pigment production.

Rutile is the preferred feedstock for the high quality-titanium industry. Titanium serves a range of industrial markets due to its remarkable properties. Titanium is highly corrosion resistant and chemically inert while offering a high strength-to-weight ratio. In its form as titanium dioxide, titanium feedstock is also essential for pigment manufacturing, for example in paints and paper.

In its metal form, titanium is as strong as steel, but 45% lighter, and twice as strong as aluminium, but only 60% heavier. As a result, the metal is used extensively in aerospace, defence, healthcare, and technology applications.

Current sources of natural rutile are in decline as several operations’ reserves are depleting concurrently with declining ore grades. These include Sierra Rutile in Sierra Leone and Base Resources’ Kwale operations in Kenya.

Additionally, global rutile supply is projected to decline sharply beyond 2023 and there are limited new deposits forecast to come online, meaning supplies of natural rutile are likely to remain in extreme structural deficit.

Despite being the preferred feedstock for the higher-quality titanium product industry, due to its scarcity, natural rutile accounts for only 5% of global titanium feedstock supply. This scarcity has prompted the titanium industry to develop upgraded feedstock products from lower-grade ilmenite that can be used as substitutes.

This high-energy and carbon-intensive process essentially removes iron oxide from the ilmenite feedstock to produce upgraded synthetic rutile and / or titania slag.

An independent, peer-reviewed, ISO-compliant life cycle analysis estimated a global warming potential of 0.1 tonnes COâ‚‚-equivalent emitted per tonne for Sovereign’s natural rutile product versus 2.0 t COâ‚‚-equivalent per tonne for titania slag production in South Africa and 3.3 t COâ‚‚-equivalent per tonne for production of synthetic rutile in Australia..

“Switching supply to Sovereign’s rutile product would be equivalent to emissions saved from taking approximately 140,000 internal combustion engine cars off European streets per year,” states Eagar.

Kasiya has a minimum production life of 25 years.

Graphite

Graphite is used in multiple industries, but demand in batteries is the high-growth area. As the anode in lithium-ion batteries, graphite can be up to 50% of an electric vehicle battery’s volume. In 2022, 3.6 million tonnes of graphite was consumed, with the battery sector accounting for 22.1%. By 2033, overall demand is forecast to reach 8.1 million tonnes, with battery’s share rising to 55.7% ; according to Fastmarkets.

Graphite is mostly processed into active anode material in China which dominates the supply chain, with almost 100% of European anode material originating in China.

With Kasiya’s natural graphite being suitable for the manufacture of active anode material, the Project is set to become the largest secure long term source of supply outside of China, producing natural graphite at an industry-low operating cost.